COMMERCIAL HEAT TREATING DIVISION

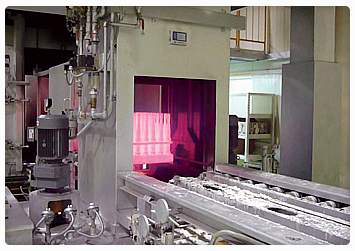

NITRIDING

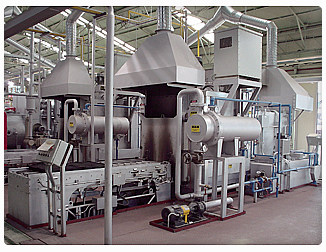

BATCH

PIT

NH3, Endothermic Gas를 이용(질화는 N2 Gas)를 이용하여 저온에서 처리하는 강의 질화법의 하나로, 변형이 극히 적고 표면에 질소 화합물층을 조절, 형성시켜 내마모, 내식, 내피로성을 향상시키는 열처리 방법입니다.

열처리 설비 방식은 Batch Type 형식과 Pit Type

형식이 있습니다.

Case-hardening process that introduces nitrogen into the surface of a solid ferrous alloy by holding the metal at a suitable temperature (below Ac1, for ferritic steels) in contact with a nitrogenous gas, usually ammonia. Does not require quenching for production of a hard case.

EXPECTED PROPERTY

- Less distortion and deformationv

- White layer gives corrosion, wear and fatigue resistance

- Better fatigue strength

- Remain inner toughness

- Workable with low carbon steel

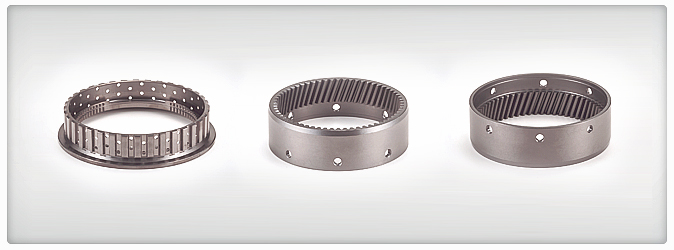

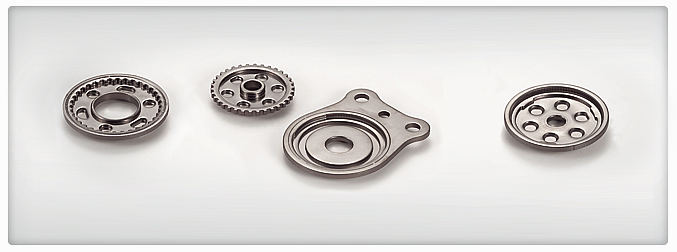

APPLICATION

- Automotive (plates, gears, parts etc.)

- Die Casting / Plastic injection molds

- Ship & aircraft parts

- Industrial, electric parts

- Hot forging molds

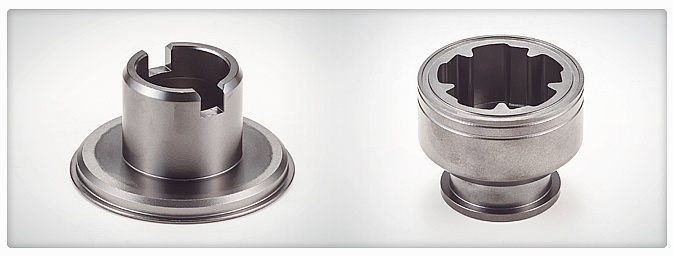

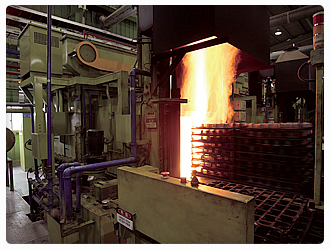

CARBONITRIDING

강의 표면에 탄소 또는 탄소와 질소를 일정 온도에서 동시에 침입시켜, 냉매에 담구어 경화시키는 방법으로 제품표면에 내마모, 내피로성 향상을 목적으로 하는 열처리 공법입니다.

침탄온도보다 다소 낮은 850℃ 부근에서 침탄분위기에 암모니아를 첨가하여 철강 내부에 탄소와 질소를 동시에 침투 확산시켜 경화시키는 방식입니다.

침탄처리에 비해 변형이 적고, 템퍼링 중 연화 저항성이 크며 피로 강도가 증가하는 장점이 있습니다.

CARBONITRIDING

Traditional case-hardening process in which carbon is dissolved in the surface layer of a low-carbon steel at a temperature sufficient to render the steel austenitic, followed by quenching and tempering to form martensitic microstructure.

Carbonitriding hardens surface of steel by diffusing carbon and nitrogen simultaneously into steel in carburizing atmosphere with ammonia gas at around 850`c, lower than typical carburizing temperature.

It offers several advantages over carburizing, including low distortion, greater resistance to softening during tempering and fatigue strength.

Operational property

- Selective hardening

- Maintain inner toughness & wear, fatigue enhancement where high frequency heated

- Stable carburized depth

- Less oxidation & decarbonizing

- Less deformation, less size scattering

Application

- Deform sensetive Automotive parts

- Industrial parts

- Vessel & aircraft parts

질화성가스와 침탄성가스를 동시에 투입하여 가공재료의 표면에 화합물층을 형성시키고 그 하부에는 확산층을 생성시킨다.

그후 최표면에 산 화분위기를 조성하여 화합물층 표면에 Fe3O4의 치밀한 산화피막을 생성시키는 공법입니다.

Oxynitriding forms Fe3O4 at the outer layer over compound layer

EXPECTED PROPERTY

- Wear ,fatigue resistance

- Fe3O4 gives better corrosion resistance

- Product color(Black & Blue)

- Alternative for hard Cr plating

- Workable with low carbon steel

APPLICATION

- Automotive (plates, gears, parts etc.)

- Die Casting / Plastic injection molds

- Industrial, electric parts

- Mold & Dies

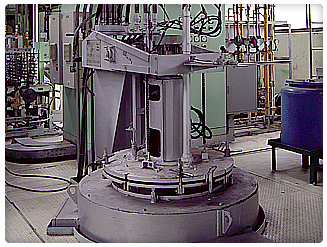

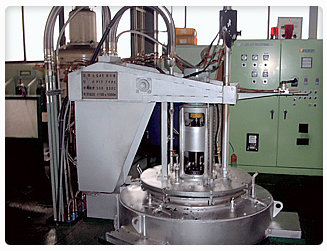

플라즈마 에너지를 이용한 질화법으로 염욕, 가스 질화에 비해 저온 에서 처리할 수 있음으로 변형제어가 가능하고 질소와 수소의 혼합가스를 사용함으로 무공해, 친환경 공정이며 혼합가스의 조성, 압력, 온도등의 조절에 의한 질화 특성이 제어 가능한 최신의 질화 신공법 입니다.

Ion nitriding extends conventional nitriding

processes using plasma discharge physics.

In a vacuum, high-voltage electrical energy is used to form a plasma through which

nitrogen ions are accelerated to impinge

on the work piece. Ion bombardment heats

the product, cleans the surface and provides active nitrogen

Plasma Nitriding

Operational property

- Precise control on diffusion layerv

- Precise temp control offers deformation stability

- Heat treating stainless

Application

- Automotive [plates, gears, parts etc.]

- Die Casting / Plastic injection molds

- Industrial, electric parts

- Mold & Dies

Feature

- Continuous Nitriding & Oxidation in same process

- Oxidation with No change in surface roughness

- Enhanced lubrication cahracteristic

- Corrosion, fatigue resistance