COATING DIVISION

APPLICATION

자동차 연비 향상을 위해 엔진폭발압력이 증가되면서 기존 열처리방법은 한계를 보이고 있습니다. 폐사에서는 이러한 가혹한 환경에서 내구성을 갖는 저마찰 코팅을 개발하여 세계 최고 수준의 품질과 국내 최대 규모의 생산능력을 보유하였습니다.

Limitations of traditional heat-treating methods make it difficult to more efficient combustion levels required in modern automobiles. Dongwoo HST offers newly developed world-class low-friction coating that could allow cars to run under such severe conditions and has the largest capacity in Korea for this application.

APPLICATION

- Automotive parts

- Industrial parts

- electronic parts

PROPERTY IMPROVEMENT

- low friction, better fuel efficiency

- enhanced durability, sticking

- Noise reduction, improved power

COATING RECOMMENDED

- DLC, Si-DLC, W-DLC

- CrN, TiAlCN

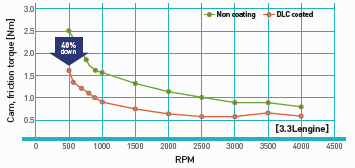

Valve lifter (Tappet) Engine rig : Gasoline 3.3 L

Valve lifter(Tappet)

- Engine rig : Gasoline 3.3 L

- Coating : DLC

- Friction coefficient : 0.05

- Friction reduction : 40% down

- Fuel efficiency : 0.8% up

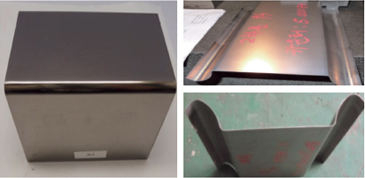

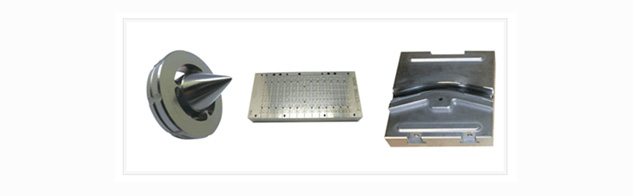

Press Mold

제품 성형에 있어 금형은 매우 중요한 역할을 담당하고 있습니다.

성형에 사용되는 판재의 두께, 인장강도, 작업온도 등의 다양한 조건에 따라 금형용 내마모 및 윤활 코팅을 제공해 드리고 있습니다.

고객의 비용절감과 작업성 향상이 가능합니다.

Press Mold

Coating provides better wear resistance and lubrication for various types of molds and dies, significantly improving the service life (a major cost factor for manufacturers) and quality of the product.

- Test condition: 250 ton press, cushion pressure 5 kgf/cm2, RPM 22-23, oil free

- Steel: 360 X 296 X 1 mm, 980 MPa AHSS

APPLICATION

- Cold Press

- Hot stamping

- Forging

PROPERTY IMPROVEMENT

- Longer Service life

- Workability

- High tension steel, SUS deep drawing

- Lubrication

COATING RECOMMENDED

- CrN, CrTiAlCN

- TiN, TiCN, TD, PN

※ 코팅별 AI 용손시험 결과

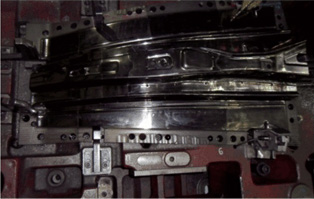

다이캐스팅 금형의 수명과 작업성 향상을 위해, 나노콤포지트 코팅을 시행하여 금형의 파손을 막고 내소착성을 개선하고 있습니다.

Nano-composite coating provides more favorable sticking properties to extend service time with fewer defects<

APPLICATION

- Al, Mg diecasting

- Insert, core pin etc.

PROPERTY IMPROVEMENT

- Longer service life

- Better Lubrication

- Less Heat check, pitting

COATING RECOMMENDED

- TiAlCrSi(C)N, CrON, TiCN, PN

Injection Mold

사출물에 의한 금형의 마모와 부식을 방지하고자 코팅을 시행합니다.

사출 품질을 향상시키고 작업성을 극대화 할 수 있습니다. 사출물과 작업온도에 따라 다양한 코팅이 적용됩니다.

Injection Mold

Coating enhances durability, anti-corrosion and anti-sticking characteristics to help increase productivity.

Various coating materials can be chosen depending on injection materials and process temperature.

APPLICATIONS

- Plastic injection mold and screw, Rubber mold, semiconductor fixture

FEATURES

- Enhancing durability of mold

- Reducing corrosion and sticking

- Increasing productivity

- Reducing releasing agent

COATINGS

- DLC, Si-DLC, CrON, TiCN, PN

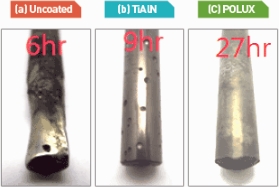

절삭공구의 PVD 고온, 내마모 코팅 적용은 이미 일반화 되어 있습니다.

고객의 사용 환경을 고려하여 신품 또는 재연삭 공구에 최적의 코팅을 제공하여드립니다.

Cutting tools have the highest requirements for surface hardness -- often, the harder the better. DONGWOO HST's PVD solution takes surface hardness to the next level with extended service life. Various types of coatings are available for every customer's need, and can even make a used tool as good as new.

APPLICATION

- Hob, Pinion cutter

- End mill, tab, drill

- High speed/nonferrous

PROPERTY IMPROVEMENT

- Wear resistance

- Faster process

- Better quality

- Less nonferrous sticking

COATING RECOMMENDED

- TiN, TiCN, TiAlN, AlTiN, DLC

Decoration

PVD공법을 이용한 금속성 감성 디자인과 기존 도장에서 불가능한 내구성을 구현할 수 있습니다.

도장과 습식도금의 환경 규제를 대응한 친환경 공법입니다.

Decoration

PVD coating can achieve exceptional design feeling and durability beyond that possible with traditional painting or plating. Great solution to environmental regulation limits associated with traditional painting and liquid plating.

APPLICATION

- Hob, Pinion cutter

- End mill, tab, drill

- High speed/nonferrous

PROPERTY IMPROVEMENT

- Wear resistance

- Faster process

- Better quality

- Less nonferrous sticking

COATING RECOMMENDED

- TiN, TiCN, TiAlN, AlTiN, DLC