INDUSTRIAL FURNACE DIVISION

VACUUM TYPE

1 CHAMBER TYPE

하나의 챔버에서 열처리를 위한 진공 또는 불활성 가스 분위기를 조성하며, 냉각 또한 가열실내에서 이루어지는 단실형 진공로입니다. 구조 및 조작이 간단하고 유지관리가 용이합니다.

고압의 질소 냉각으로 강력한 냉각력과 균일 냉각으로 큰 제품의 열처리가 가능하며, 표면에 제품산화가 없는 열처리 설비 입니다.

1 CHAMBER TYPE

Low pressure atmosphere for heat treating, quenched in same position. Easy control and maintenance.

STANDARD SPECIFCATIONS OF 1 CHAMBER TYPE VACUUM FURNACE

| Capacity | Max. Vacuum | Cooling pressure | Heating Capacity | Cooling gas | |||

|---|---|---|---|---|---|---|---|

| Model | size(mm) | MAX. Temperature (c) | (kg/gross) | (torr) | (bar) | (KW) | |

| DHEV-243624 | 600W*900L*600H | 1350 | 500 | 10^-3 | 6, 10, 15 | 190 | N2 GAS |

| DHEV-324432 | 800W*1100L*800H | 1350 | 1000 | 10^-3 | 6, 10, 15 | 270 | N2 GAS |

FURNACE FEATURE

- Single chamber

- Switchable cooling gas flow (up&down)

- Compact size(inner heat exchanger)

- Simple design, low maintenance cost

PROCESS OPTIONS

- AGING

- HARDENING

- SOLUTION ANNEALING

- BRAZING etc.

PRODUCTS

- HIGH SPEED STEEL (SKH51, 55, 57 etc.)

- STAINLESS STEEL

- TOOL STEEL

- TITANIUM ALLOY etc.

2 CHAMBER TYPE

가열실과 냉각실이 따로 구성된 2실형 진공로로서 1실형에 비해 효과적인 냉각성능을 지니고 있습니다.

옵션에 따라 여러가지 열처리가 가능합니다. Q/T, 침탄 등 선택된 열처리 종류나 처리제품의 크기에 따라 가스 또는 오일을 이용한 냉각방식을 선택할 수 있으며, 가스냉각의 경우 불활성 가스를 이용하여 최고 10bar의 압력까지 가능합니다.

Gas퀜칭시 1실형 보다 빠른 냉각 성능을 낼 수 있어 대형금형 하이스 제품 열처리가 용의 합니다.

2 CHAMBER TYPE

Separated chamber for heating and cooling. Higher cooling efficiency than a single chamber. Various types of heat treating possible for different demands.

Either gas or oil cooling can be chosen depending on size of the work piece and heat treating method. Cooling pressure with gas can be operated up to 10 bar.

STANDARD SPECIFCATIONS OF 2 CHAMBER TYPE VACUUM FURNACE

| Effective Size (mm) | Heater (Kw) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Width | Length | Height | Capacity | Furnace | Oil Tank | Cooling | Pressure (bar) | Remarks |

| 600 | 900 | 600 | 600kg | - | - | CUSTOM FURNACE WHEN NEEDED |

|||

| 600 | 900 | 600 | 600kg | 6, 10, 15 | 6, 10, 15 | ||||

| 760 | 1200 | 750 | 1000kg | 4.5KW | - | - | |||

| 760 | 1200 | 750 | 1000kg | 6, 10, 15 | 6, 10, 15 | ||||

FURNACE FEATURE

- Faster cooling(than 1 chamber type)

- Gas, oil or salt quenching

- Suitable for large charge and molds

PROCESS OPTIONS

- AGING

- HARDENING

- SOLUTION ANNEALING

- BRAZING etc.

PRODUCTS

- HIGH SPEED STEEL (SKH51, 55, 57 etc.)

- STAINLESS STEEL

- TOOL STEEL

- TITANIUM etc.

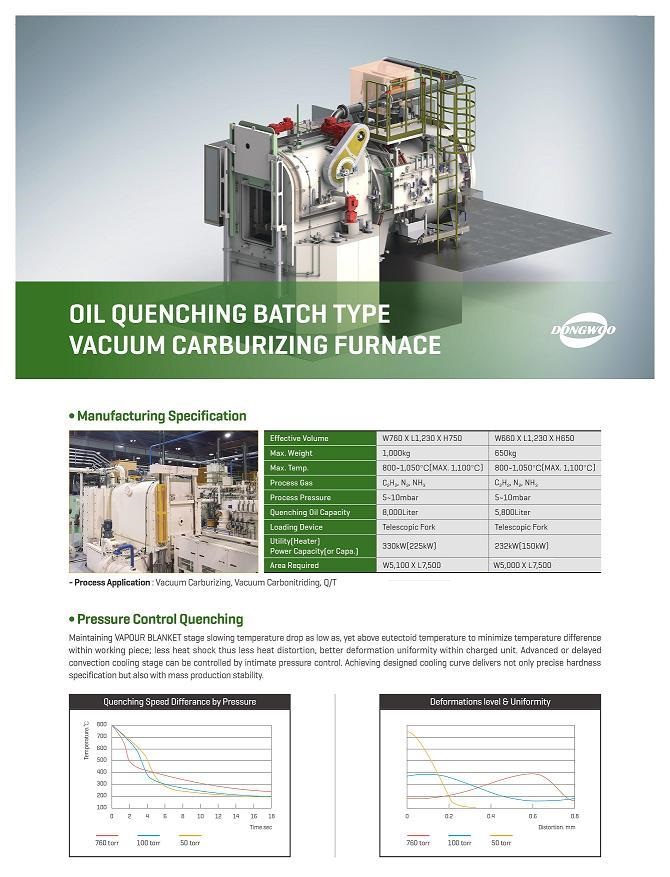

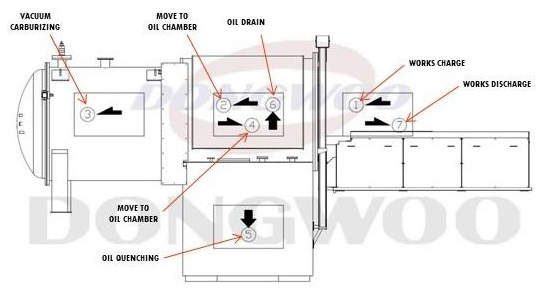

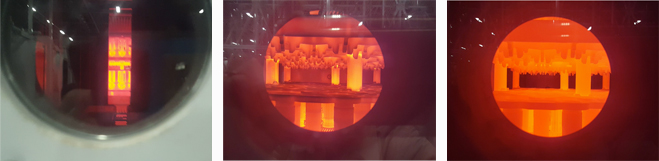

OIL QUENCHING VACUUM CARBURIZING

PROCESS SEQUENCES

DOUBLE TRACK TYPE VACUUM CARBURIZING

Quenching Process

- Optimize Cooling Speed before & after this quench stop to reach compromise distortions.

- Control of oil surface pressure in vacuum can reduce distortion significantly.

DOUBLE TRACK TYPE VACUUM CARBURIZING

CATALOGUE DOWNLOAD- Vacuum carburizing continues to gain market share due to its reduced process time and more environmentally-friendly technology.

- Vacuum carburizing has gained a significant market share for the new generation of trans-missions such as dual clutch(DCT) and six- and eight-speed automated transmissions

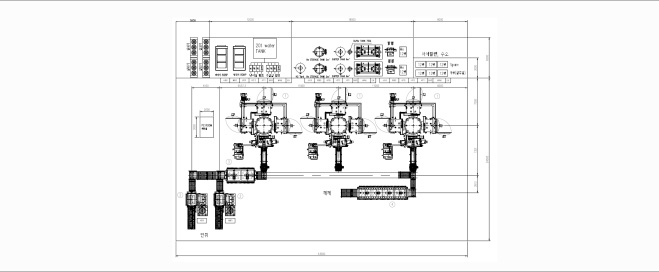

STAR TYPE VACUUM CARBURIZING

Specification

- Composition. Heating chamber 3+ Transfer Cell 1 + Quenching cell 1

- Capacity 800kg. Gloss charge. (W600*H750*L1000)

- Temperature. Max. 1100Đ, ± 5Đ / Graphite

- Vacuum Pressure. Max. ↖ 5x10-2 mbar, control 5-20mbar

- Gas. Max. 10 m3/hr C2H2, N2, NH3(optional)

- Heating chamber. Convection heating system, Graphite insulation

- Transfer device. In-Out type Telescopic Fork, Turn Table

- Quenching type Max. 20 bar high pressure gas (N2 or Hel)

- Optional utility He Recycling system (optional): 200 m3/hr

STAR TYPE VACUUM CARBURIZING

CATALOGUE DOWNLOAD

ION NITRIDING

플라즈마 에너지를 이용한 질화법으로 염욕, 가스 질화에 비해 저온에서 처리할 수 있음으로 변형제어가 가능하고 질소와 수소의 혼합가스를 사용함으로 무공해, 친환경 공정이며 혼합가스의 조성, 압력, 온도 등의 조절에 의한 질화 특성이 제어 가능한 최신의 질화 신공법입니다

ION NITRIDING

Ion nitriding is an extension of conventional nitriding processes using plasma discharge physics.

In a vacuum, high-voltage electrical energy is used to form a plasma through which nitrogen ions are accelerated to impinge on the work piece.

Ion bombardment heats the product, cleans the surface and provides active nitrogen.

STNDARD SPECIFICATIONS OF NITRIDING FURNACE

| Effective Size (mm) | |||||

|---|---|---|---|---|---|

| Model | Width | Length | Height | Weight (Kg/ch) | Remarks |

| DNR21GE-2431224SF | 610 | 7,925 | 610 | 250 | CUSTOM FURNACE WHEN NEEDED |

| DNR21E-2433624Q | 610 | 8,535 | 610 | 250 | |

| DNR21GE-2433624S | 610 | 8,535 | 610 | 250 | |

| DNR21E-2436024Q | 610 | 9,145 | 610 | 250 | |

| DNR21E-2438426S | 610 | 9,754 | 610 | 250 | |

FURNACE FEATURE

- Batch type(in&out, straight), vertical

- Ion plasma

NITROCARBURIZING

- Low temp treating using NH3, RX Gas

- Technology management friendly

- Wear, corrosion, fatigue resistance

- Short process time(0.5~3h)

OXYNITRIDING

- Use NH3, endothermic Gas

- Forms Oxidized layer at the outer layer for enhanced corrosion resistance

- Wear, fatigue resistance

- Fine color(dark blue)

ION-NITRIDING

- Forms plasma using N2, H gas under vacuum

- Environment friendly process

- Less distortion(relatively low temp)

- Process variable limited to mixed gas, pressure and temperature

- Simple property control