COMMERCIAL HEAT TREATING DIVISION

CARBURIZING

GAS CARBURIZING

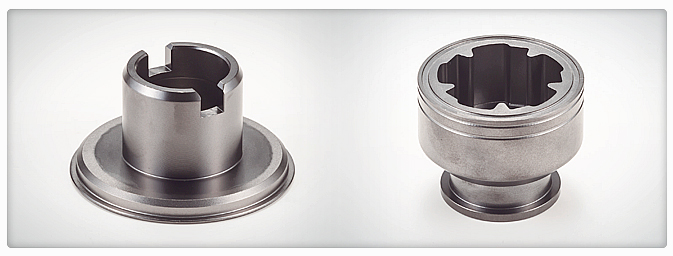

강의 표면에 탄소 또는 탄소와 질소를 일정 온도에서 동시에 침입시켜, 냉매에 담구어 경화시키는 방법으로 제품표면에 내마모, 내피로성 향상을 목적으로 하는 열처리 공법입니다.

침탄온도보다 다소 낮은 850℃ 부근에서 침탄분위기에 암모니아를 첨가하여 철강 내부에 탄소와 질소를 동시에 침투 확산시켜 경화시키는 방식입니다.

침탄처리에 비해 변형이 적고, 템퍼링 중 연화 저항성이 크며 피로 강도가 증가하는 장점이 있습니다.

GAS CARBURIZING

Traditional case-hardening process in which carbon is dissolved in the surface layer of a low-carbon steel at a temperature sufficient to render the steel austenitic, followed by quenching and tempering to form martensitic microstructure.

Carbonitriding hardens surface of steel by diffusing carbon and nitrogen simultaneously into steel in carburizing atmosphere with ammonia gas at around 850℃ lower than typical carburizing temperature.

It offers several advantages over carburizing, including low distortion, bigger resistance to softening during tempering and fatigue strength.

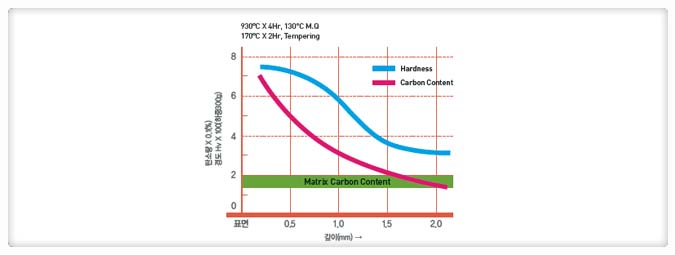

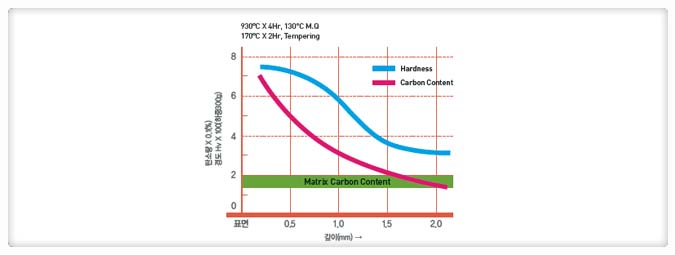

HARDNESS PROFILE BY CARBON CONTENT

EXPECTED PROPERTY

- Enhanced Wear & Shock resistance

- Uniform case depth & Easy control

- Carbonitriding

- Less distorsion with lower process temp

- Lower carbon steel(plates) enable

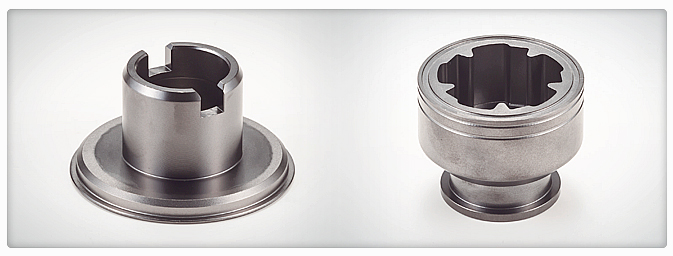

APPLICATION

- Automotive parts

- Industrial parts

- Ship & aircraft parts

GAS CARBONITRIDING

강의 표면에 탄소 또는 탄소와 질소를 일정 온도에서 동시에 침입시켜, 냉매에 담구어 경화시키는 방법으로 제품표면에 내마모, 내피로성 향상을 목적으로 하는 열처리 공법입니다.

침탄온도보다 다소 낮은 850℃ 부근에서 침탄분위기에 암모니아를 첨가하여 철강 내부에 탄소와 질소를 동시에 침투 확산시켜 경화시키는 방식입니다.

침탄처리에 비해 변형이 적고, 템퍼링 중 연화 저항성이 크며 피로 강도가 증가하는 장점이 있습니다.

GAS CARBONITRIDING

Traditional case-hardening process in which carbon is dissolved in the surface layer of a low carbon steel at a temperature sufficient to render the steel austenitic, followed by quenching and tempering to form martensitic microstructure.

Carbonitriding hardens surface of steel by diffusing carbon and nitrogen simultaneously into steel in carburizing atmosphere with ammonia gas at around 850℃ lower than typical carburizing temperature.

It has several advantages such as low distortion, bigger resistance of softening during tempering, and fatigue strength over carburizing.

HARDNESS PROFILE BY CARBON CONTENT

EXPECTED PROPERTY

- Enhanced Wear & Shock resistance

- Uniform case depth & Easy control

- Carbonitriding

- Less distorsion with lower process temp

- Lower carbon steel(plates) enable

APPLICATION

- Automotive parts

- Industrial parts

- Ship & aircraft parts

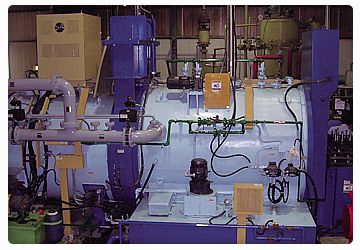

GAS QUENCHING

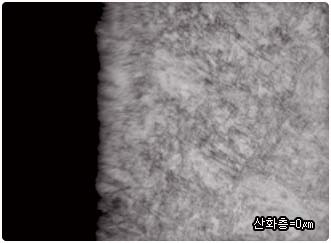

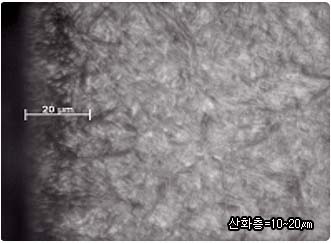

가스 침탄 처리와는 달리 저 진공의 무산화 분위기상태에서 침탄 처리를 함으로써 단 시간내에 탄소를 소재표면에 침투, 확산시킨 후 Gas로 퀜칭하는 열처리 방법입니다.

Non-equilibrium, boost-diffusion carburizing process in which steel being processed is austenitized in a rough vacuum, carburized in a partial pressure of hydrocarbon gas, diffused in rough vacuum and then quenched with gas.

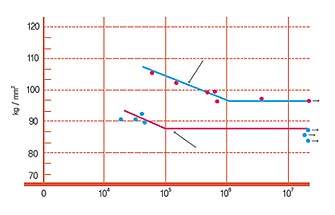

HARDNESS PROFILE BY CARBON CONTENT

경화깊이가 동일한 SNCM23H의 회전굽힘 피로시험의 결과 진공침탄 처리를 실시한 제품이 일반가스 침탄을 실시한 시험편보다 피로강도가 약 15% 향상됨을 보임

Fatigue strength comparison test shows 15% improvement on SNCM23H when vacuum carburized.

EXPECTED PROPERTY

- No oxidation layer

- High density carburazing

- Enhanced fatigue strength

- Clean(bright) product

- Easy carburizing in small holes

- Clean environment

APPLICATION

- Automotive parts

- industrial parts

- ship & aircraft parts

- Tool parts(SKD, SKH etc.)

- Brazing

OIL OR SALT QUENCHING

가스 침탄 처리와는 달리 저 진공의 무산화 분위기상태에서 침탄 처리를 함으로써 단 시간내에 탄소를 소재표면에 침투, 확산시킨 후 Oil 또는 Salt로 퀜칭하는 열처리 방법입니다.

None equilibrium, boost-diffusion carburizing process in which steel being processed is austenitized in a rough vacuum, carburized in a partial pressure of hydrocarbon gas, diffused in rough vacuum, and then quenched With Oil or Salt.

EXPECTED PROPERTY

- No oxidation layer

- High density carburazing

- Enhanced fatigue strength

- Clean(bright) product

- Easy carburizing in small holes

- Clean environment

APPLICATION

- Automotive parts

- industrial parts

- ship & aircraft parts

- Tool parts(SKD, SKH etc.)

- Brazing